How to Save Thousands for An Engineering Department By Switching to Cloud CAD

Recently I covered the best computer hardware for engineering students in a piece for Engineering.com. In doing so it became clear there was a bit of a disconnect between industry and academia. This is partially due to the ability of companies to invest in new technology and employ people to keep things running smoothly. Providing the staff and infrastructure to manage new technologies is key to being able to adopt them.

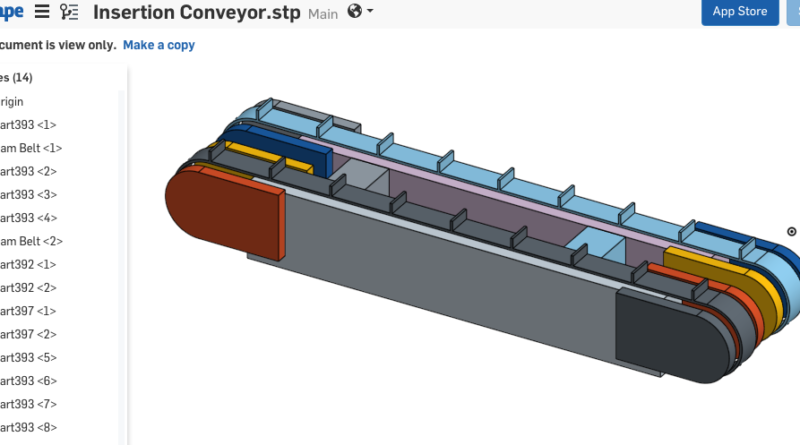

One company doing this is FEMC, a packaging and machinery company. One of their engineers, Chris Winters, shared a piece about how he shifted their entire engineering department over to Chromebooks. This shift away from traditional workstations was enabled thanks to cloud services like Onshape.

I reached Chris by email to get his take on the hardware shift in industry and how it relates to the academic market.

3dNPD: When moving to chromebooks what additional training did you require within the organization?

CW: We are still ongoing with our development in the full use of Chromebooks. There is an application to use that completely replaces the offerings of a standard tower. Google’s apps are in depth and can easily export to any windows based platform. The hardest part is changing peoples notions of decades of repetition and that, ” you have to back it up!” mentality that the cloud removes. Most apps continuously update and save the changes you make on the fly. The ability to access the information across multiple platforms(i.e. Towers, laptops, tablets, smartphones) is truly advantageous.

3DNPD: Compared to the hardware you learned on in school what is the setup you have experienced in the working world?

CW: The manufacturing world is experiencing a true paradigm shift in engineering, R&D

manufacturing, and data analysis. I learned on AutoCad, with minimal exposure to Inventor and Solidworks. Both were truly powerful tools but when the student license runs out, that’s it.

Google SketchUp was a great step in the right direction, but was so limited that I couldn’t afford a full seat. College is expensive as everyone knows and with limited funds every penny counts.

The pinch with modern manufacturing you have to hit the ground running, there is a very limited learning curve and dedicated seats make it truly difficult to grasp new concepts and applications outside of the office.

Onshape cut the very real tether that engineering has had to deal with. I can access tutorials, videos, and ongoing webinars where ever i am throughout my schedule. All I need is a wifi hotspot and I am off to the races, while still protecting my companies IP to boot.

3DNPD: Are there any skills that you see as non-transferable depending on what hardware someone learns and trains on during their education?

CW: I have not come across a single tower based application that does not have a cloud-based competitor. The biggest challenge is the ability to watch the tutorials( today’s equivalent of reading the manual), asking questions during any training, and going on message boards and asking others who have already gone through the growing pains.

As far as engineering courses, Onshape may not be the required platform, but it has a strength and flexibility that can and will meet current and future curriculum at most colleges. It has the ability to export in every type of file that is used in today’s classrooms. Your teacher wants projects in .STEP, .STL, DWG, .DXF? Onshape seamlessly exports these and many more platforms with zero problems. Working on a group project? multiple partners can work on the same model real time and collaborate right now. You can work on multiple versions of the same model and then collaborate on which choices should be included into the final version. I have done all of these things on a Chromebook, tablet, and a fifth generation smartphone for my company and real world applications.

Big thanks to Chris for taking the time to answer our questions.

Are you using Onshape in coursework or the working world? Want to share a cool project with 3dNPD? If so let us know in the comments below.