How Rapid Prototyping Accelerates Product Launches in Competitive Markets

When you’re racing to launch a product before your competitors, time isn’t just money—it’s market share. In today’s fast-paced innovation cycles, speed can make or break your go-to-market strategy. From hardware startups to legacy manufacturers pivoting into new markets, shaving weeks—or even days—off the development timeline can mean capturing attention before someone else does.

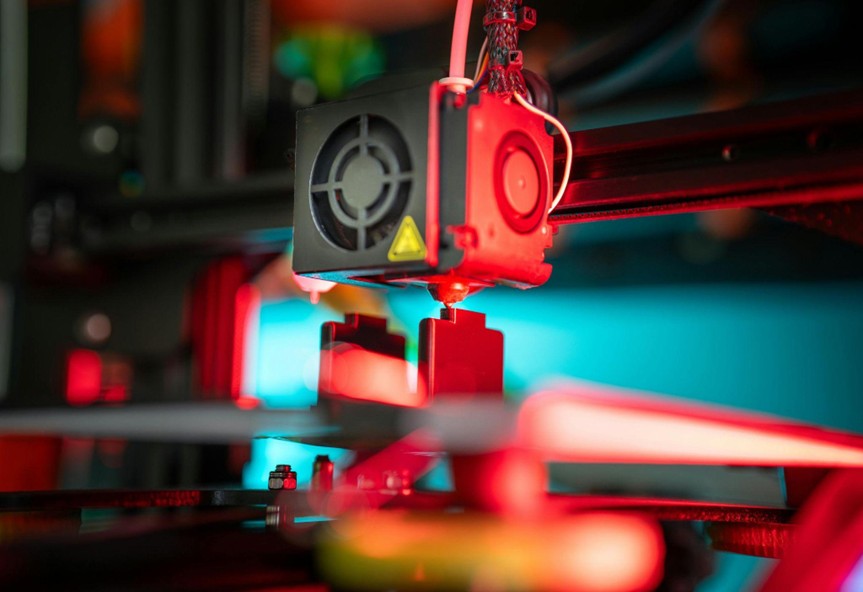

That’s where rapid prototyping steps in. It closes the gap between concept and production by transforming digital designs into tangible parts in record time. For businesses under pressure to iterate fast, validate ideas quickly, and move confidently toward production, it’s not just a helpful tool—it’s a necessity.

In this guide, 3E Rapid Prototyping Company explores how rapid prototyping fuels smarter product launches—and why it’s a cornerstone of modern manufacturing success.

What is Rapid Prototyping, Really?

Rapid prototyping is the process of quickly fabricating a physical model or part from a digital design using advanced manufacturing technologies. It allows businesses to test functionality, refine designs, and identify flaws early—without the delays of full-scale production.

Unlike traditional prototyping, which often involves manual fabrication or lengthy tooling phases, rapid prototyping leverages digital workflows to compress timelines. The goal isn’t just to make a part—it’s to make a part fast enough to inform the next step in your development.

It’s important to distinguish between prototyping and production. Prototypes are temporary, functional representations used to validate ideas. Production parts, on the other hand, are built for final use—often in high volumes and with more stringent cost and quality constraints.

Common rapid prototyping methods include:

- 3D Printing (Additive Manufacturing) – Ideal for fast, low-volume iterations

- CNC Machining – Great for precision metal or plastic components

- Urethane Casting – Useful for simulating injection-molded parts in small quantities

- Sheet Metal Prototyping – Quick turnarounds for brackets, enclosures, or chassis

- Injection Molding (Bridge Tooling) – Suitable for functional prototypes in production-grade plastics

- Laser Cutting – Fast 2D profiling for flat parts and custom fixtures

Why Is Rapid Prototyping So Critical for Competitive Markets?

In hyper-competitive industries, getting your product to market first—or at least on time—can mean the difference between growth and stagnation. Rapid prototyping plays a critical role by drastically reducing the time it takes to go from idea to viable design.

By shortening development cycles, companies can pivot faster, test more frequently, and launch with greater confidence. Instead of waiting weeks for tooling, teams can test functional parts overnight. This agility isn’t just convenient—it’s a competitive edge.

Here are some of the most valuable business advantages:

- Reduced risk of failure through early testing and validation

- Faster feedback loops with real user input before launch

- Lower development costs due to fewer design errors

- Greater investor confidence with tangible prototypes to demonstrate

- Accelerated innovation cycles with tighter iteration loops

The companies thriving in today’s markets are the ones that don’t hesitate to prototype early and often.

How Does Rapid Prototyping Fit Into the Product Development Cycle?

Modern product development is no longer a linear process—it’s iterative, fast-paced, and deeply collaborative. Rapid prototyping fits seamlessly into each stage of this lifecycle, from the earliest sketches to the final tweaks before production.

At the start, it supports idea validation, letting you test if your concept is even worth pursuing. Then, as designs mature, it enables multiple design iterations without the overhead of retooling. For products that need to function under real-world conditions, functional testing with rapid prototypes uncovers critical insights.

Eventually, you may use bridge tooling or low-volume production runs to create parts that mimic production-grade materials and finishes, ideal for market testing or regulatory feedback.

Here’s how the flow typically looks:

- Idea validation – Translate concepts into testable models

- Design iterations – Adjust forms, features, and dimensions quickly

- Functional testing – Assess real-world performance and usability

- Bridge tooling – Create molds or tools for short-run parts

- Market testing – Gather user feedback before scaling up

This flexibility ensures you’re not locked into costly decisions too early—because rapid prototyping is built to adapt.

What Are the Main Types of Rapid Prototyping Technologies?

There’s no one-size-fits-all approach to prototyping. The right method depends on your material needs, design complexity, desired turnaround time, and intended use. Let’s break down the most widely used technologies and when to use them.

3D Printing (Additive Manufacturing)

How it works: Builds parts layer by layer from digital files using a variety of 3D printing materials, including thermoplastics, resins, and metal powders.

Typical turnaround time: 1–3 days

Material compatibility: PLA, ABS, Nylon, TPU, photopolymer resins, metals

Pros:

- Fast and cost-effective for complex geometries

- No tooling required

- Great for early concept validation

Cons:

- Surface finish may require post-processing

- Limited mechanical strength (depending on material)

CNC Machining

How it works: Subtractive process where material is cut away from a solid block using computer-controlled tools.

Typical turnaround time: 2–7 days

Material compatibility: Aluminum, steel, ABS, POM, PC, and more

Pros:

- High dimensional accuracy

- Wide range of functional materials

- Production-quality surface finishes

Cons:

- More expensive than 3D printing for single units

- Longer setup time for complex parts

Urethane Casting

How it works: A master pattern (often 3D printed) is used to create silicone molds. Urethane resins are cast into these molds to replicate parts.

Typical turnaround time: 7–15 days

Material compatibility: Urethane resins simulating ABS, rubber, or polycarbonate

Pros:

- Mimics injection-molded quality

- Good for 10–100 units

- Broad range of textures and hardness levels

Cons:

- Mold degradation after repeated use

- Slower than direct 3D printing or machining for one-off parts

Sheet Metal Prototyping

How it works: Uses cutting, bending, and forming processes to shape thin metal sheets into enclosures or brackets.

Typical turnaround time: 5–10 days

Material compatibility: Steel, stainless steel, aluminum

Pros:

- Fast turnaround for functional parts

- Ideal for electronics enclosures or structural supports

Cons:

- Limited to relatively simple geometries

- Tolerances can vary with complexity

Injection Molding for Prototypes (Bridge Tooling)

How it works: Uses aluminum tooling to create small batches of injection-molded parts.

Typical turnaround time: 10–20 days

Material compatibility: Most production plastics, including ABS, PP, PC

Pros:

- Close match to final production parts

- Useful for regulatory testing or user trials

Cons:

- Higher upfront cost than other prototyping methods

- Not suitable for highly iterative designs

Laser Cutting

How it works: High-powered lasers cut flat materials with extreme precision. The choice of laser cutting materials — such as metals, plastics, and wood — directly affects the quality, speed, and application of the final cut.

Typical turnaround time: 1–3 days

Material compatibility: Acrylic, wood, metal sheets, rubber

Pros:

- Very fast for 2D profiles

- Great for gaskets, brackets, or custom signage

Cons:

- Limited to flat parts

- No 3D form creation

Which Materials Are Commonly Used in Rapid Prototyping—and Why?

The choice of material can make or break your prototype’s success. It influences everything from performance under stress to surface finish, flexibility, and even user perception. Different prototyping methods support different materials, and choosing the right one is crucial to getting usable feedback or ensuring accurate functional tests.

Here are the most common categories used in prototyping:

- Plastics – Lightweight, versatile, and ideal for testing form and fit

- Metals – Durable, machinable, and perfect for functional testing

- Elastomers – Offer flexibility and impact resistance

- Resins – Used for high-detail parts or aesthetic presentation models

ABS

A widely used thermoplastic with good strength and impact resistance.

- Key Properties: Rigid, durable, easy to machine or print

- Applications: Enclosures, mechanical parts, snap fits

Polycarbonate (PC)

Stronger and more temperature-resistant than ABS.

- Key Properties: High impact resistance, optical clarity

- Applications: Lenses, casings, load-bearing parts

Nylon (PA12, PA6)

Tough and flexible, ideal for high-wear applications.

- Key Properties: Wear resistance, fatigue tolerance

- Applications: Hinges, gears, fixtures

TPU and Other Flexible Materials

Rubber-like flexibility with good resilience.

- Key Properties: Elasticity, impact absorption

- Applications: Seals, gaskets, flexible connectors

Aluminum

Lightweight and machinable, ideal for structural prototypes.

- Key Properties: Strength-to-weight ratio, corrosion resistance

- Applications: Housings, brackets, heat sinks

Stainless Steel

Heavy-duty, corrosion-resistant, and durable.

- Key Properties: Strength, chemical resistance

- Applications: Medical devices, aerospace, functional testing

Urethane Resins

Simulate a range of thermoplastics, from rubbery to rigid.

- Key Properties: Customizable hardness and finish

- Applications: Low-volume production, functional models

What Are the Stages of Rapid Prototyping?

Rapid prototyping follows a predictable yet flexible process that supports multiple design iterations before committing to tooling.

- Conceptualization – Turn abstract ideas into early sketches

- CAD Design – Create digital models in software like SolidWorks or Fusion 360

- 3D Printing / Machining – Fabricate initial parts using additive or subtractive methods

- Finishing – Polish, paint, or sand for realistic presentation or testing

- Testing – Assess performance, fit, and usability

- Iteration – Refine based on insights

- Pre-production – Prepare for scale-up with bridge tooling or low-volume runs

What Problems Does Rapid Prototyping Help Solve in Product Launches?

In high-stakes launches, small mistakes can lead to massive setbacks. Rapid prototyping helps businesses identify—and eliminate—issues early, when changes are still affordable.

- Reduces cost of failure

- Reveals design flaws early

- Helps secure funding with tangible demos

- Enhances user testing for better UX

- Avoids tooling delays and rework

- Speeds up compliance processes in regulated industries

How Can You Design Smarter for Prototyping?

Designing with prototyping in mind reduces errors, speeds up production, and lowers costs.

- Design for material constraints – Not all materials behave the same way

- Consider process limitations – Avoid overly thin walls or unsupported features

- Use clean file formats – STL and STEP are industry standards

- Plan for iteration – Leave room for future changes

- Include fit/assembly features – Consider snap fits, press fits, or joints

CAD Design Tips for Speed and Accuracy

- Avoid over-detailing early-stage parts

- Minimize overhangs and unsupported spans

- Maintain consistent wall thickness

- Use chamfers and fillets wisely

- Validate mesh before printing

Tolerances and Fit Considerations

- Use loose fits for first iterations

- Account for material shrinkage

- Recognize different tolerances in CNC vs. 3D printing

What Are Common Mistakes to Avoid in Rapid Prototyping?

- Over-designing for looks before function

- Choosing unsuitable materials for stress testing

- Ignoring design-for-manufacturing principles

- Assuming prototype quality = production quality

- Skipping user feedback and iterative testing

How Do You Scale from Prototype to Production Without Starting Over?

Successful transition relies on design continuity and manufacturability.

- Refine DFM (Design for Manufacturability)

- Swap prototype materials for production-grade ones

- Choose the right manufacturing partner early

- Leverage bridge tooling for low-volume runs

Conclusion

Rapid prototyping isn’t just a tool—it’s a strategic accelerator. In a landscape where launching late often means losing the race, the ability to iterate quickly, test thoroughly, and move confidently to production gives businesses a critical advantage.

From concept sketches to pre-production parts, prototyping reduces cost, mitigates risk, and sharpens product-market fit. Whether you’re refining a hinge on a wearable or validating an engine component, your path from prototype to production could be the edge that sets your company apart.

If speed, precision, and adaptability matter to your next launch, it’s time to rethink how you build—starting with how you prototype.